- Home

- About Us

- Products

- TD High-efficiency And Energy-saving Circulating Pump

- TD High-efficiency And Energy-saving Circulating Pump Accessories

- Pipeline Pump

- Pipeline Pump Accessories

- Sewage Pump

- Sewage Pump Accessories

- LG Multi-stage Pump

- LG Multi-stage Pump Accessories

- Cooling Tower Circulation Pump

- Electric Motor

- Electric Motor Accessories

- News

- Contact Us

- Home

- About Us

- Products

- TD High-efficiency And Energy-saving Circulating Pump

- TD High-efficiency And Energy-saving Circulating Pump Accessories

- Pipeline Pump

- Pipeline Pump Accessories

- Sewage Pump

- Sewage Pump Accessories

- LG Multi-stage Pump

- LG Multi-stage Pump Accessories

- Cooling Tower Circulation Pump

- Electric Motor

- Electric Motor Accessories

- News

- Contact Us

Web Menu

- Home

- About Us

- Products

- TD High-efficiency And Energy-saving Circulating Pump

- TD High-efficiency And Energy-saving Circulating Pump Accessories

- Pipeline Pump

- Pipeline Pump Accessories

- Sewage Pump

- Sewage Pump Accessories

- LG Multi-stage Pump

- LG Multi-stage Pump Accessories

- Cooling Tower Circulation Pump

- Electric Motor

- Electric Motor Accessories

- News

- Contact Us

Product Search

Exit Menu

What are the recommended maintenance intervals and procedures for the multistage pump?

Maintenance intervals and procedures for multistage pumps can vary depending on the specific make and model, as well as the manufacturer's recommendations. However, here are some general guidelines:

Daily Inspection: Check for any leaks, unusual noises, or vibrations during operation. Ensure that the pump is running smoothly without any apparent issues.

Weekly Inspection: Monitor pump performance metrics such as flow rate, pressure, and temperature. Inspect seals, bearings, and couplings for any signs of wear or damage. Lubricate bearings as necessary.

Monthly Maintenance: Check alignment of pump and motor shafts. Inspect impellers, diffusers, and other internal components for wear or damage. Clean pump internals if necessary. Inspect motor and electrical connections for any issues.

Quarterly Maintenance: Perform more detailed inspections of pump internals, including checking clearances, tightening fasteners, and replacing worn parts as needed. Verify alignment of pump and motor shafts.

Annual Maintenance: Disassemble pump for thorough inspection and cleaning. Replace seals, bearings, and other components as recommended by the manufacturer. Check alignment and balance of impellers and shafts. Inspect motor windings and electrical connections.

Overhaul: Depending on the pump's usage and operating conditions, a major overhaul may be required every few years. This involves disassembling the pump, inspecting all components, replacing worn parts, and reassembling the pump with new seals and bearings.

It's important to follow the manufacturer's specific recommendations for maintenance intervals and procedures outlined in the pump's operation and maintenance manual. Additionally, keeping detailed records of maintenance activities and any issues encountered can help identify trends and optimize the pump's performance and longevity.

Related Products

-

Horizontal pipeline pump body

Cat:Pipeline Pump Accessories

The pump body consists of two main parts: suction chamber and pressure...

See Details -

Pipe pump horizontal base

Cat:Pipeline Pump Accessories

The pump base serves to support and secure the pump casing. Horizontal...

See Details -

Sewage pump cast iron impeller

Cat:Sewage Pump Accessories

The impeller is the core component of a sewage pump, responsible for r...

See Details -

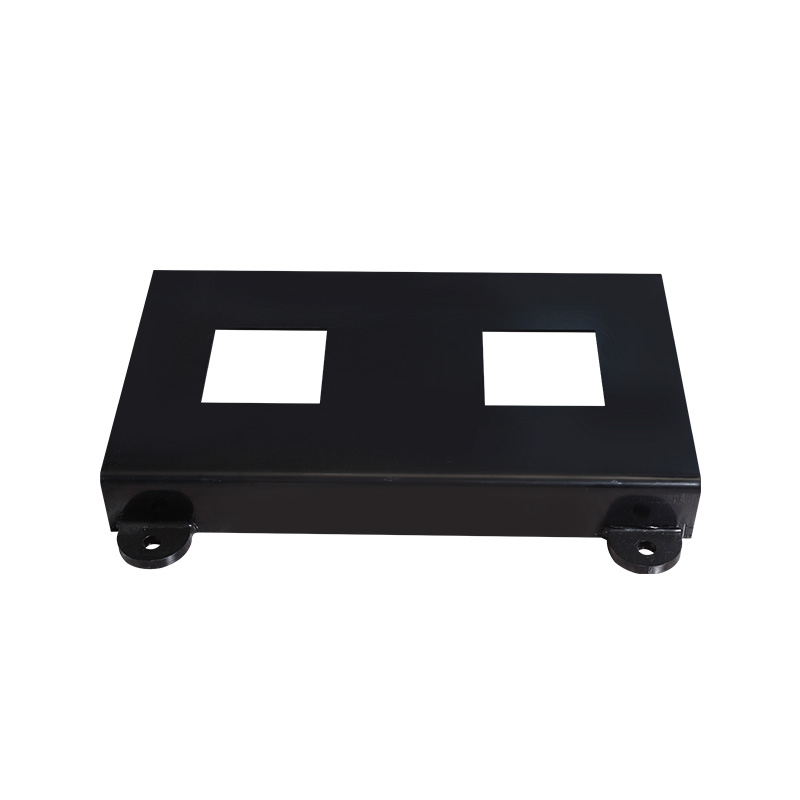

Sewage pump foot plate

Cat:Sewage Pump Accessories

Components mounted on the bottom of the sewage pump unit to support th...

See Details -

LG multi-stage pump 150 series

Cat:LG Multi-stage Pump

Operating conditions 1. It can convey clear water or non-corrosive med...

See Details -

LG multi-stage pump water outlet section

Cat:LG Multi-stage Pump Accessories

The outlet section is the outlet part of the pump, which is responsibl...

See Details -

LG multi-stage pump coupling

Cat:LG Multi-stage Pump Accessories

Couplings are used to connect the pump shaft to the motor shaft for en...

See Details -

B3/B35 Horizontal inverter motor

Cat:Inverter Electric Motor

Also known as base mounting, the motor is connected to the mounting da...

See Details -

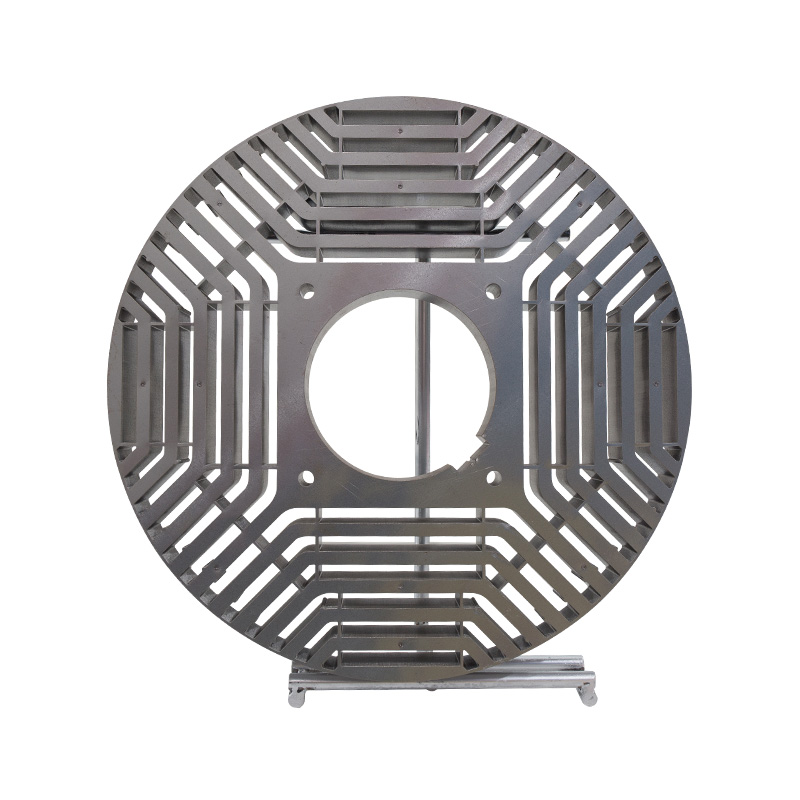

Permanent magnet core stator and rotor

Cat:Electric Motor Accessories

A type of rotor core that uses a permanent magnet material to achieve ...

See Details -

TD horizontal high-efficiency energy-saving circulation pump

Cat:TD High-efficiency And Energy-saving Circulating Pump

1.TD horizontal high-efficiency and energy-saving circulation pump is ...

See Details

- TD High-efficiency And Energy-saving Circulating Pump

- TD High-efficiency And Energy-saving Circulating Pump Accessories

- Pipeline Pump

- Pipeline Pump Accessories

- Sewage Pump

- Sewage Pump Accessories

- LG Multi-stage Pump

- LG Multi-stage Pump Accessories

- Cooling Tower Circulation Pump

- Electric Motor

- Electric Motor Accessories

-

+86-0563-2251312

-

+86-0563-2251311

-

+86-139 6620 0379

-

-

No.43 Guohua Road, Guangde Economic Development Zone, Xuancheng City, Anhui Province, China