- Home

- About Us

- Products

- TD High-efficiency And Energy-saving Circulating Pump

- TD High-efficiency And Energy-saving Circulating Pump Accessories

- Pipeline Pump

- Pipeline Pump Accessories

- Sewage Pump

- Sewage Pump Accessories

- LG Multi-stage Pump

- LG Multi-stage Pump Accessories

- Cooling Tower Circulation Pump

- Electric Motor

- Electric Motor Accessories

- News

- Contact Us

- Home

- About Us

- Products

- TD High-efficiency And Energy-saving Circulating Pump

- TD High-efficiency And Energy-saving Circulating Pump Accessories

- Pipeline Pump

- Pipeline Pump Accessories

- Sewage Pump

- Sewage Pump Accessories

- LG Multi-stage Pump

- LG Multi-stage Pump Accessories

- Cooling Tower Circulation Pump

- Electric Motor

- Electric Motor Accessories

- News

- Contact Us

Web Menu

- Home

- About Us

- Products

- TD High-efficiency And Energy-saving Circulating Pump

- TD High-efficiency And Energy-saving Circulating Pump Accessories

- Pipeline Pump

- Pipeline Pump Accessories

- Sewage Pump

- Sewage Pump Accessories

- LG Multi-stage Pump

- LG Multi-stage Pump Accessories

- Cooling Tower Circulation Pump

- Electric Motor

- Electric Motor Accessories

- News

- Contact Us

Product Search

Exit Menu

What are the environmental conditions at the multistage pump installation site (e.g., temperature extremes, humidity, dust)?

The environmental conditions at an multistage pump installation site can vary greatly depending on the specific location and the type of installation. Here are some common factors to consider:

The range of temperatures the site experiences, including the highest and lowest temperatures that can be expected. This is important for equipment that has temperature sensitivity.

The amount of moisture in the air, which can affect the performance and longevity of electronic and mechanical equipment. High humidity can lead to corrosion and condensation issues.

The presence of dust, dirt, and other particles in the air can affect the operation of machinery and the health of workers. Dust can also be a fire hazard in some cases.

Changes in atmospheric pressure can affect the performance of certain equipment, especially at high altitudes.

High winds can affect the stability of structures and the operation of outdoor equipment.

The amount and type of rainfall, snowfall, or other forms of precipitation can impact the site, especially if there is a risk of flooding or water damage.

The amount of natural and artificial light available can affect visibility and the need for additional lighting.

The presence of vibrations from nearby machinery or traffic can affect sensitive equipment.

High noise levels can impact workers' health and the operation of certain types of equipment.

The presence of corrosive or harmful chemicals in the air or soil can affect equipment and safety.

The presence of pests, mold, or other biological factors that could affect the health of workers or the integrity of the installation.

The risk of earthquakes, which can affect the stability and design of structures.

The type of soil (e.g., clay, sand, rock) can affect the stability of foundations and the need for special construction techniques.

The availability of water, electricity, and other utilities can affect the design and operation of the installation.

When planning an installation, it's important to conduct a thorough site survey to understand all relevant environmental conditions and to design the installation to withstand these conditions. This may involve selecting appropriate materials, designing for temperature and humidity control, and ensuring that the installation is resilient to local weather patterns and other environmental factors.

Related Products

-

Vertical TD high-efficiency and energy-saving circulation pump

Cat:TD High-efficiency And Energy-saving Circulating Pump

The TD type single-stage pipeline circulation pump is a green, environ...

See Details -

Horizontal pipeline pump body

Cat:Pipeline Pump Accessories

The pump body consists of two main parts: suction chamber and pressure...

See Details -

Pipeline pump B14 pump cover

Cat:Pipeline Pump Accessories

The pipeline pump B14 pump cover is a specific type of pump cover for ...

See Details -

Pipeline pump cast iron impeller

Cat:Pipeline Pump Accessories

The impeller refers to both the disc with moving blades, which is an i...

See Details -

Ordinary sewage pump

Cat:Sewage Pump

1. Our WQ-type general sewage pump adopts a large flow channel anti-cl...

See Details -

Sewage pump casing

Cat:Sewage Pump Accessories

The casing of the sewage pump unit plays a role in protecting the inte...

See Details -

LG multi-stage pump water inlet section

Cat:LG Multi-stage Pump Accessories

The inlet section is the inlet portion of the pump and is responsible ...

See Details -

LG multi-stage pump stainless steel impeller

Cat:LG Multi-stage Pump Accessories

Stainless steel impellers are impellers made of stainless steel materi...

See Details -

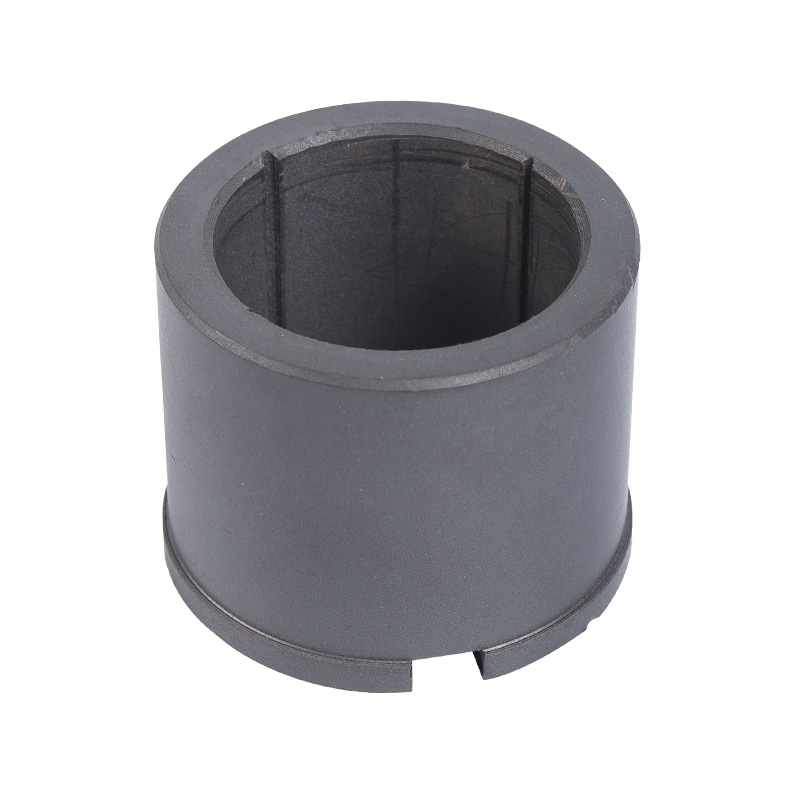

LG multi-stage pump water bearing

Cat:LG Multi-stage Pump Accessories

Water bearings are a special type of bearings commonly used in multi-s...

See Details -

Finished stator

Cat:Electric Motor Accessories

The stator of a motor refers to the fixed part which contains the stat...

See Details

- TD High-efficiency And Energy-saving Circulating Pump

- TD High-efficiency And Energy-saving Circulating Pump Accessories

- Pipeline Pump

- Pipeline Pump Accessories

- Sewage Pump

- Sewage Pump Accessories

- LG Multi-stage Pump

- LG Multi-stage Pump Accessories

- Cooling Tower Circulation Pump

- Electric Motor

- Electric Motor Accessories

-

+86-0563-2251312

-

+86-0563-2251311

-

+86-139 6620 0379

-

-

No.43 Guohua Road, Guangde Economic Development Zone, Xuancheng City, Anhui Province, China